MANUFACTURING SERVICES

PRECISION CNC MACHINING

FULLY AUTOMATED CNC MACHINING SERVICES

Your business requires CNC machining services that create a competitive advantage in your industry.

This is achieved by providing quality goods, stable costs, and reliable delivery. The business’ manufacturing process must be streamlined with the utmost precision to edge out your competition.

Fully automated

CNC machining services from GN Corporations will enable your company to take advantage of our data-driven GN 4.0 platform that uses machine learning and artificial intelligence to reliably deliver a wide range of quality parts and tools.. Working with the leading custom CNC machining parts manufacturer, you’ll never have to worry about quality or delivery delays again.

Custom CNC Machining Services: 5 Axis and 9 Axis Machining and Turning

5-Axis CNC Machining

In a single operation, our 5-axis CNC machine has the ability to manufacture customized polyhedrons and intricate structural parts.

9-Axis CNC Machining & Turn

With the CNC 9-Axis machining and turning machine, your CNC partner can create high-performance parts in various materials and intricate shapes.

5-Axis Water Jet Cutters & Wire EDM

Like the conventional 5-Axis machine, this variant employs water jet cutters or wires to work with diverse materials while maintaining structural integrity during the cutting process.

OUR ADVANCED CNC MACHINING CAPABILITIES ARE DESIGNED FOR QUALITY

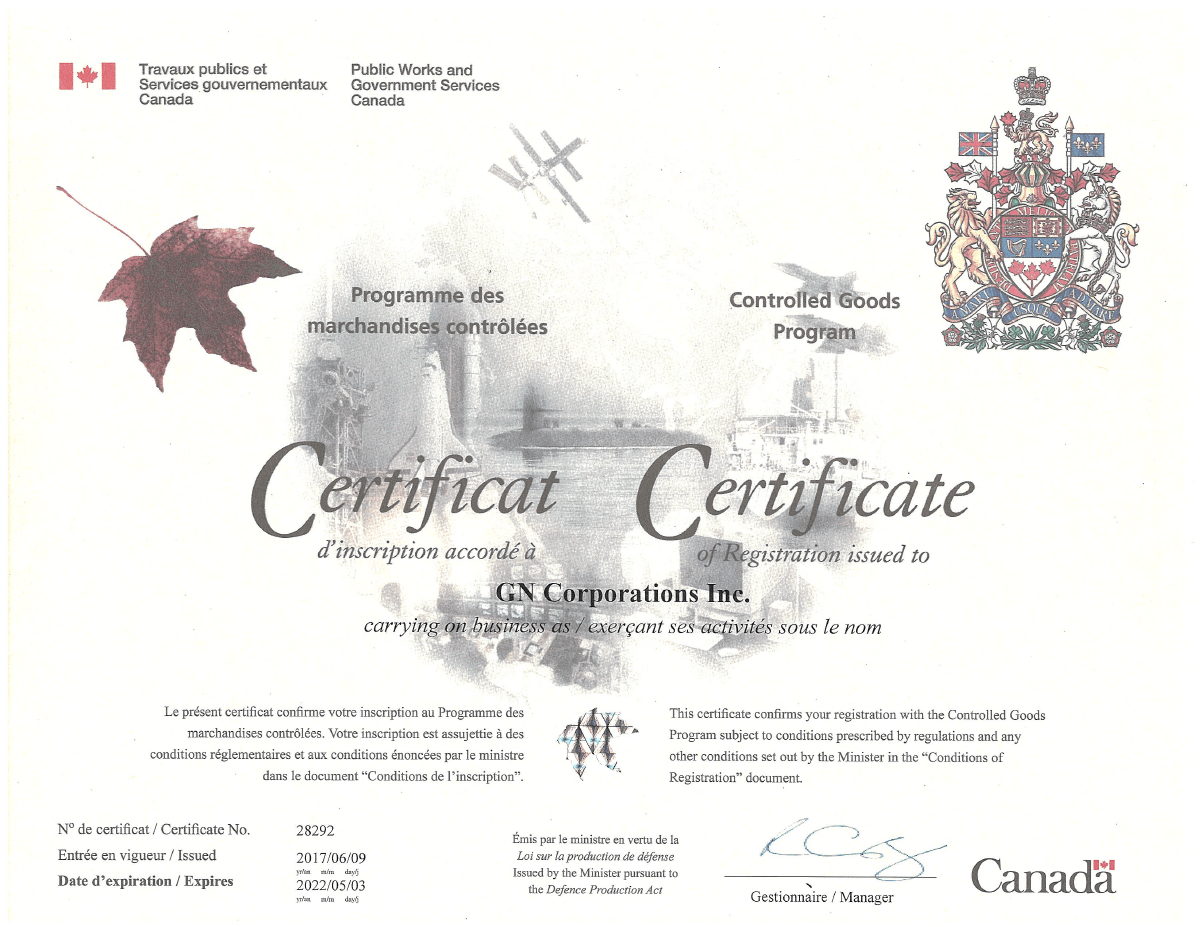

We have developed a proprietary technology suite we call GN 4.0. Using the industrial internet of things, artificial intelligence, and advanced machining capabilities our qualified and AS9100D certified machine shop provide advanced precision machining to the Aerospace, Automotive, Oil & Gas and Defense sectors.

Our commitment to quality and service with our ISO 9001:2015 and AS9100D certified quality management system, has helped us build a reputation for integrity, which in turn has led to long-lasting relationships with our customers and suppliers. GN Corporations is proud to offer all of the machining capabilities your company requires:

A STATE OF THE ART MANUFACTURING FACILITY

Our manufacturing facility contains over 50 multi-axis CNC machines that can handle almost any project that you’ll send our way.

AUTOMATED CELLS WITH VARIETY

We have approximately 20 automated cells, both 5 and 9 axis cells, that allow our machining services to carry out numerous specialized tasks with incredibly high precision.

THE RIGHT TOOLS

Our manufacturing facilities are equipped with the most advanced machine tools, including 5-Axis CNC milling machine, 9-Axis CNC mill & turn, gun & deep-hole drilling machinery, five-axis water jet cutters, & wire EDM.. We leverage advanced systems and the latest software to ensure a seamless outcome for your projects.

CNC Machining Industry Applications

AUTOMOTIVE

CNC machining allows the automotive industry to increase the efficiency of both prototyping and production. Automotive CNC machining can include cylinder blocks, valves, axles, and gearboxes — all components that require precision and durability.

AEROSPACE

The aerospace industry requires precision machining to produce durable, lightweight components. That’s why aerospace CNC machining has become the standard for many safety-critical components. Additionally, the range of alloys used with CNC machining is ideal for the variety of applications found in aerospace.

OIL & GAS

Components found throughout the oil and gas industry require strict tolerances and corrosion resistance. CNC machining is able to work with a range of alloys with precision to meet these needs. Use cases include pistons, rods, valves, and cylinders in pipelines or refineries.

DEFENSE

A CNC machining manufacturer is capable of producing high-durable, complex components that are often required by the defense industry. Equipment and components used in this industry need to withstand wear and tear while also performing as expected without faults. CNC machining is able to meet these demands.

TECHNOLOGY & CONSUMER ELECTRONICS

The tech world utilizes CNC machining manufacturers for specific components. Use cases include PCBs, fixtures, housings, and many other components. CNC can also handle rapid prototyping and move right into production, which is often needed by tech.

Are you ready to see how our custom CNC machining services can revolutionize your processes?

STREAMLINE YOUR ENTIRE PROCESS WITH OUR VALUE ADDED SERVICES

We hear it all the time, a new client will tell us that they have products machined at one CNC machine shop, only to have them shipped somewhere else for assembly, protective coating, and other processes that must be completed before the product is completed. The transportation costs alone eat into production costs, plus the opportunity for logistical issues to disrupt production.

Our additional value-added services are designed to complete as many processes as you desire to get you closer to the finished product. Or even all the way there.

Get your project completed without investing in expensive equipment. You can pick any of our services to outsource your manufacturing needs and accelerate your production timeline.

We Offer:

- Complete Assembly

- Hard Facing

- Welding

- Brazing

- Hydrostatic Pressure testing

- Liquid Penetrant Inspection

- Magnetic Particle inspection

- Zinc Phosphate Coating

- Fluoropolymer Coating

- Molybdenum Coating

- Induction Hardening

- Enamel Coating

- Sandblasting/Shot Peen

- Crating/Packaging

- Primer Coat per Military Spec.

- Powder Coat per Military Spec

- C.A.R.C. Painting per Military spec.

- Chromate per ASTM B449-93, Class 3

Experience Our Unmatched Advanced Machining Services

We have over five decades of machining experience behind us, and we’ve been adopting advanced technologies every step of the way. Our staff and technicians have the required knowledge and skills needed to ensure your manufacturing experience is seamless from start to finish.

Our services make use of the latest advancements in industrial IoT, automation, machining technologies, and artificial intelligence to better serve our clients.

Each technology has been meaningfully adopted into our machining services to enhance the precision and speed of our services.

Are you ready to work with a machining company that has focused on quality for over 50 years and strives for continuous improvement? Reach out to us today to see how our advanced machining services can revolutionize your manufacturing processes.