SERVICES

QUALITY ASSURANCE IN CNC MANUFACTURING

QUALITY ASSURANCE THAT ENSURES SAFETY AND COMPLIANCE

Your project must be safe for end users and comply with all applicable regulations, regardless of whether you’re building aerospace components, automotive components, or mining equipment.

GN Corporations is a tier-1 manufacturer with a robust CNC manufacturing quality assurance process that leverages the latest technology to test our work and deliver top-quality results.

GET STARTEDDRIVEN BY GN 4.0

TIER-1 SUPPLIER

CWB CERTIFIED

industries we serve

GN has earned a reputation for excellence across several industries that must have high-quality manufacturing services. For years, we’ve kept customers happy in several essential industries, including:

our quality assurance services

GN Corporations has pioneered integrating the latest quality assurance technology into our manufacturing processes to deliver top-quality results — every time. We use the latest in computer vision, probing tools, and machine learning to guarantee the quality of our end products.

Our ongoing emphasis on using the latest technological advancements throughout our CNC manufacturing and quality assurance processes ensures that our customers only receive high-quality results. Some of the tools and technologies we use include:

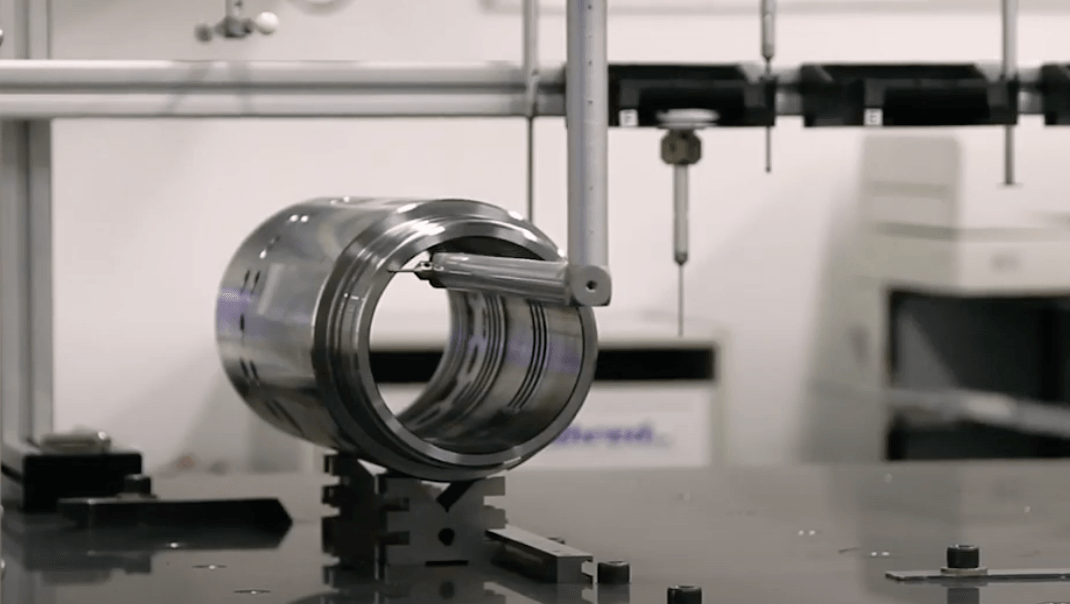

zeiss contura

Zeiss Contura is the latest advancement in fine-tuned manufacturing with a four axis rotary table, plenty of sensors, and first-class performance. As a result, the Zeiss Contura has become the standard in commercial manufacturing and integrates perfectly with GN 4.0.

- Optical sensors for ultra-precise measurements and triangulation lasers.

- It is integrated with the GN 4.0 process due to its Zeiss Smart Services, allowing for real-time performance monitoring.

- Predictable performance, keeping your project on schedule at all times.

ABSOLUTE ARM 7 AXIS

The Absolute Arm 7 Axis is designed for productivity and versatility, allowing GN to measure, scan, and confirm the quality of everything we do before it’s shipped to our customers. The Absolute Arm has earned its place in manufacturing due to providing the reliability and functionality the industry requires.

- Constructed with advanced high-tech carbon fiber tubes, giving the Arm 7 Axis has the strength and thermal stability to function accurately in most manufacturing environments.

- ISO Certified for usage as a complete scanning system and providing accurate probing accuracy; we only use the best.

- Effortlessly moves as necessary for our quality assurance purposes, allowing us to keep your project on schedule.

Renishaw Tool Probe

Taking apart your project to ensure quality would be slow and inefficient. Fortunately, the Renishaw Tool Probe allows us to test each component without needing to take each part off the machine.

EQUATOR GAUGING SYSTEM

We use the Equator Gauging System to test the temperature and overall integrity of everything we manufacture. This specialized system allows us to work with more significant parts while still ensuring the accuracy of the results.

- Capable of a larger measuring volume than other models, such as a truck transmission or engine casing, without jeopardizing accuracy.

- New IPC software allows for constant monitoring and managing process control limits.

- Rapid temperature changes are no longer an issue, as the Equator can handle a range of over 45 degrees Celsius.

GN 4.0: Your Leading-Edge CNC Manufacturing Partner

Explore our high-tech, proven CNC manufacturing process that puts the latest technology to work to ensure efficient and quality-first results. Our GN 4.0 platform is already deployed and under continual refinement to allow us to embrace the latest advancements in artificial intelligence, automation, and machine learning, implement quality excellence — all for the ultimate benefit of our customers.

Our GN 4.0 platform grants you access to leading-edge manufacturing processes that deliver the quality-driven results you need.

WHY WORK WITH GN

Partner with GN Corporation for Certified Quality Assurance Manufacturing

Ready to learn why our customers keep coming back? Book a call with one of our manufacturing specialists to learn how we’ll manufacture the top-tier results you need.

book a consultation