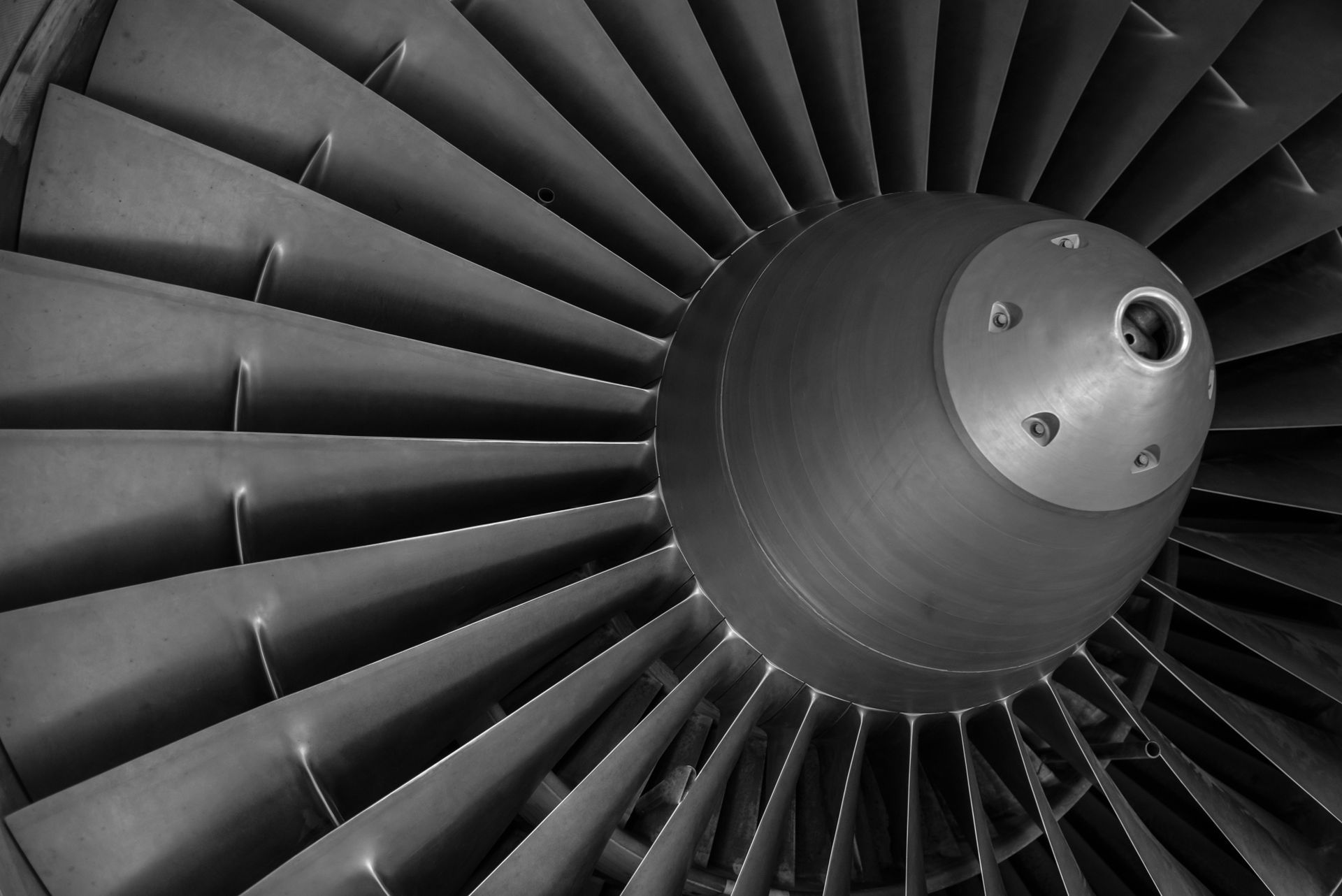

CNC MACHINING SERVICES FOR THE AEROSPACE INDUSTRY

Leverage GN Corp’s CNC machining services to manufacture durable, high-quality aircraft parts.

GN Corp is a leader in precision aerospace CNC machining parts, and we have the experience, equipment, and reputation for taking on even the most challenging orders.

learn more

WHY DOES THE AEROSPACE INDUSTRY USE CNC MACHINING?

High-quality aerospace machined parts are essential for organizations throughout the industry. However, aerospace is also a highly regulated industry, necessitating working with a CNC machining partner with the proper certifications and experience to keep you compliant.

GN’s aerospace CNC machining parts go through multiple quality assurance products that give you all of the benefits of this specialized machining process, such as:

- Producing complex, custom parts at scale

- Focuses on dependability and quality

- Ready to work with nearly any type of material your project requires

- Manufacture the parts you need on time and on budget

Aerospace precision parts CNC machining can take on complex tasks that demand accuracy. Working with GN Corporations ensures your aerospace parts are of the highest quality and ready to work.

BENEFITS OF USING CNC MACHINING FOR AEROSPACE PARTS

- Superior Performance: Failure in aerospace components can be devastating, which is why the industry is highly regulated and scrutinized. Parts must meet stringent performance, tolerance, and dimensional requirements. CNC machining makes these attributes possible without increasing costs.

- Lightweight: Aerospace parts must be light so the aircraft can take off and reduce fuel consumption while in flight. CNC aerospace machining can produce thin-walled components and work with necessary alloys to produce strong yet lightweight components ready for flight.

- High Efficiency: CNC machining leverages automation to achieve higher per-part speeds and shorten overall production cycles. GN’s Industry 4.0 processes leverage machine learning and automation throughout our workflows to save time without sacrificing quality.

- Reliable Precision: One primary reason why CNC machining aerospace parts has become so popular is because of the need for precision while tackling complex designs. CNC provides better accuracy and control to minimize defects and produce high-quality components.

- Affordability: Per-part costs can be decreased when CNC machining is leveraged for rapid production. Manufacturers can reduce waste, labour hours, and rework due to the combination of automation and precision. Reducing defects creates significant savings for the entire batch.

AEROSPACE CNC MACHINING APPLICATIONS IN AVIATION AND SPACEFLIGHT

CNC machining is widely used throughout aviation, aerospace, and spaceflight to manufacture components that demand precision and durability. Common use cases include valve components, electrical connectors, filter bodies, and oxygen generation components. Any faults in these areas can be devastating, leading companies to use CNC precision machining.

MATERIALS FOR AEROSPACE MACHINED PARTS

- Aluminum Alloy Series 2xxx: This series of alloys is combined with copper to create a high-strength and workable alloy. Precision aerospace CNC machining parts manufacturers use this alloy for machined parts such as fuselage structures and airplane wings.

- Aluminum Alloy Series 6xxx: By using magnesium and silicon, this alloy series is one of the most versatile aluminum alloys. The material provides better corrosion resistance, formability, and strength compared to some other options. Series 6xxx is widely utilized throughout many industries.

- Aluminum Alloy Series 7xxx: Series 7xxx focuses on using zinc as the primary alloying element and can also include magnesium, copper, or chromium. The resulting alloy is strong and durable, making it widely used in defense and aerospace.

OUR CNC MACHINING CAPABILITIES

Unique CNC machining capabilities are why aerospace parts CNC machining manufacturing is one of the top methods in the industry. Multi-axis machines are at the core of this method.

Some of the most common CNC machines are:

9-Axis CNC Mill & Turn

Choosing the 9-Axis milling machine allows your CNC partner to manufacture more complex shapes, which is often necessary for the highly specialized components in the aerospace industry.

5-Axis Water Jet Cutters & WIRE EDM

Similar to the standard 5-Axis milling machine, this version uses water jet cutters or wires to take on different materials without jeopardizing integrity with cuts.

frequently asked questions

What types of materials are commonly used in CNC machining for aircraft parts?

Most of the aircraft parts CNC machining we manufacture for our clients use the following materials:

- Aluminum

- Steel

- Titanium

Some of our clients also request CNC machining plastic aircraft parts depending on their specific needs.

How does CNC machining compare to other manufacturing methods for aerospace components?

The effectiveness of any manufacturing method is dependent on its application. Generally, CNC machining for aircraft components is one of the top manufacturing methods. However, organizations must pick the right CNC machining aerospace parts supplier to realize its benefits.

How does the design of an aerospace component affect the CNC machining process?

The component’s design affects which machine tools can be used and what cutting tools are necessary. The design also affects the depth of cuts and the overall speed of the machining process.

Each of these variables necessitates working with a CNC machining aerospace parts factory with the right tools and experience for your specific order.

What are the advantages and disadvantages of CNC machining for aerospace components?

CNC machining aerospace parts factories have the advantage of providing both speed and quality, often resulting in a cost-competitive product for clients. However, CNC machining can be overly costly in some situations when another method is favorable.

How can the precision and accuracy of CNC machining aerospace parts be ensured?

Quality control equipment is vital to ensuring the manufactured components are up to specifications. Accuracy and precision are critical in aerospace manufacturing, so it’s essential to find precision aerospace CNC machining parts manufacturers.

How can CNC machining be used to create complex geometries and shapes for aerospace components?

CNC machines are highly sophisticated, can reach tight tolerance, and can articulate various directions to manufacture complex components. The capability to take on complicated components quickly and reliably is essentially why many clients seek out a reputable CNC machining aerospace parts manufacturer.

What are the steps involved in the CNC machining process for aerospace components?

Generally speaking, the process begins by roughing out the parts to get close to the right shape and size, then are slowly machined to the correct size. Going from a rough approximation to the end result is often multiple operations.

How does CNC machining affect the lead time and cost of producing aerospace components?

CNC machining is the fastest way to produce parts, so this method provides the best opportunity for competitive cost and lead time for components

How can CNC machining be used to produce small quantities of custom aerospace components?

One advantage of CNC machines is that they are capable of doing any quantity of products as long as they fit within the machine’s size capability. The independence from large quantities is one reason companies choose production CNC machining for aerospace parts.

Are there any special considerations for CNC machining of titanium and other high-strength materials for aerospace components?

Yes, we consider the movement of material during the CNC machining process. Evaluating all possibilities is essential for a final quality result. Therefore, when evaluating CNC machining aerospace parts manufacturers, including these criteria is essential.

How does CNC machining cope with aerospace components’ high temperature and pressure requirements?

CNC machining processes and programs can be adjusted to compensate for challenging materials, pressures, and temperatures. The versatility of this type of manufacturing is primarily why CNC machining has become so popular in aerospace.

Are there any special surface finishes requirements for aerospace components that can be achieved by CNC machining?

Yes, CNC machining can achieve extremely tight tolerances to a certain point, allowing for a range of surface finishes that are typically necessary for aerospace applications. GN has become a leader in production CNC machining manufacturers for aerospace parts by providing a range of in-demand finishes.

How does CNC machining comply with aerospace industry standards and certifications?

CNC machining provides the means to achieve industry standards; in some cases, processes will need to be certified to a standard. Aerospace is a tightly regulated industry, so working with a manufacturing partner that understands these regulations and has all the necessary certifications is essential.

How does CNC machining handle the weight reduction demands for aerospace components?

CNC machining handles weight reduction demands exceptionally well. In addition, CNC machining has a wide variety of applications and can deal with several different materials, allowing companies like GN to handle weight reduction tasks.

Make GN Corporation Your CNC Manufacturing Partner for Aerospace Parts

You need a certified, reputable, and dependable CNC manufacturing partner to take on your next order. Our CNC machining aerospace parts quotes consider all the elements of your order so we can provide you with both a cost and time estimate.

Ready to keep your project on budget and on time? Contact GN Corporations today to get a quote for aerospace CNC machining.

BOOK A CONSULTATION