industries

CNC PRECISION MACHINING

FOR THE OIL & GAS INDUSTRY

SUPPORTING THE WORLD’S ENERGY

Stress-Tested, Custom-Designed Products Built for the Oilfield

Any oil and gas industry operation depends on durable, precise equipment and machinery to protect workers and improve efficiency. Additionally, any component found in oil and gas must meet strict standards and specifications. Any variation from these standards can result in serious issues, making CNC precision machining a highly sought-after manufacturing method for the oil and gas industry.

get started

Components GN Manufactures for the Oil and Gas Industry

GN’s CNC machining can produce a wide range of components necessary throughout the oil and gas industry. We’re ready to process custom requests or standard components, such as:

- Actuating system components

- Directional drilling components

- Completion tool components

- Production tool components

- High Pressure, High Temperature (HPHT) components

- Valve (Gate, Choke, Check) components

- Polymer components (Seals, Elements, O-rings)

- Sealing systems

- Shafts

- Connectors

- Fasteners

- Hydraulic components

- Pump System components

What materials does GN CNC machining work with?

Our CNC machining equipment can work with a variety of different materials to suit the specific component, including:

- Low Alloy Steels

- Corrosion Resistant Alloys (Stainless Steels, Inconel, Incoloy)

- Chrome (9 CR, 13 CR, 25 CR)

- Aluminum (7075, 6061)

- Copper (BeCu)

- Magnesium

- Titanium

- Composite

STABILITY AMIDST VOLATILITY

Changing government regulations, environmental policies, and new advancements in technology means oil and gas companies need to find the right partners to accelerate and prioritize their outcomes in the field and across the industry as a whole.

You need to streamline and automate whatever manual processes you can. You must leverage connected sensors and digitization for greater visibility and efficiency. And you must ensure that each component is composed of the highest-quality materials possible.

Here’s where we come in.

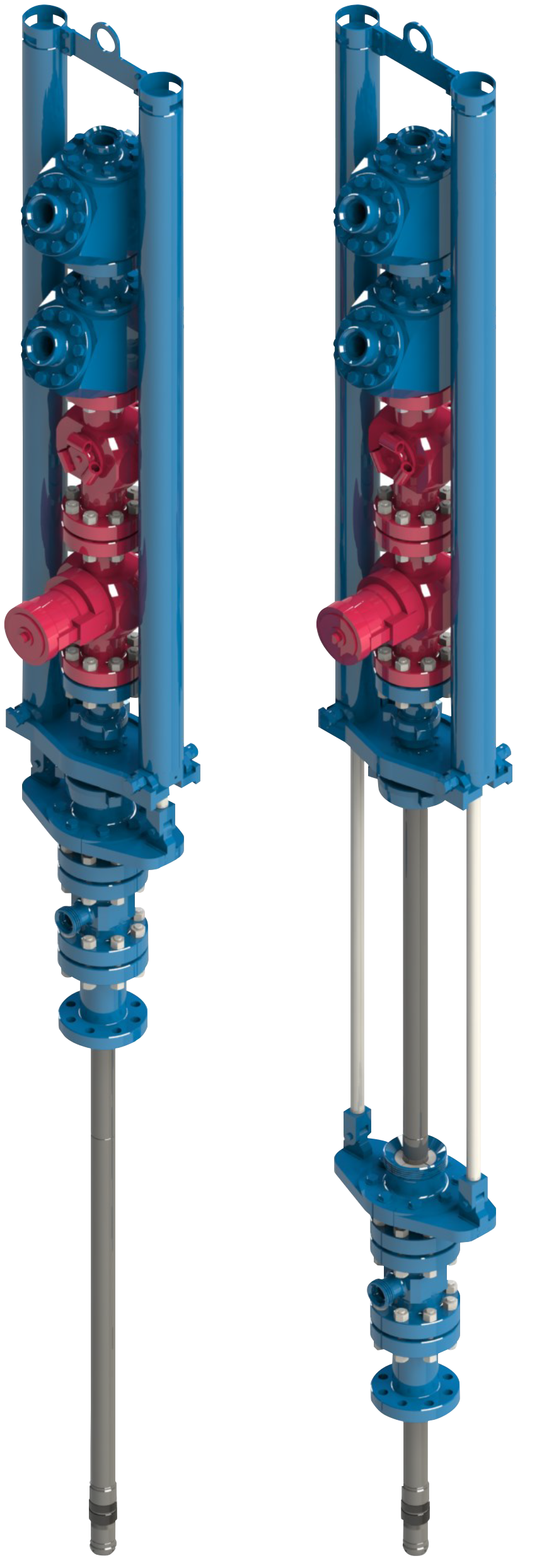

GN Wellhead Isolation Tool

Preserve your everyday wellhead with GN’s wellhead isolation tool for high-pressure stimulation treatments. Our stress-tested isolation tool is manufactured per specific regulations, including API 6A, ANSI/NAC, MR0175, and DNV.

There’s no need to kill your well to install and use our isolation tool. Keep your oil and gas operations on schedule while protecting your daily-use wellheads during well stimulation treatments.

LEARN MORE ABOUT OUR WELLHEAD ISOLATION

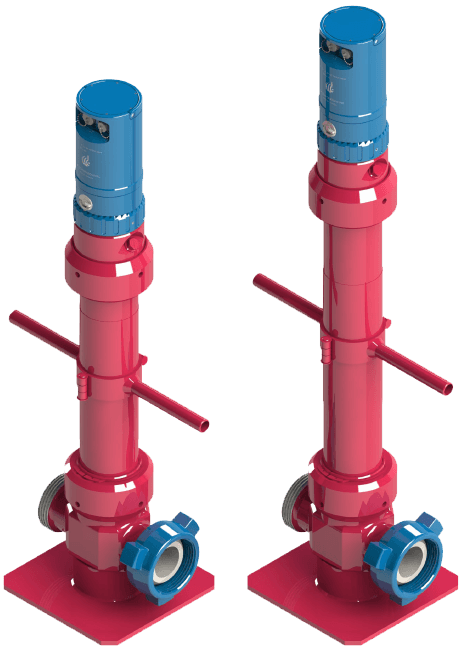

GN BALL INJECTOR

Protect against damage during your stimulation treatments with GN’s top-tier ball injectors designed for dependable performance. Our components are designed for automatic or manual ball injection into pressurized acid treatments to seat against perforations before applying increased pressure.

Minimize fluid loss, improve flowback, and repair wellbore damage with our line of ball injectors. designed to meet ISO 9001, AS91000D requirements, and other industry compliance standards.

LEARN MORE ABOUT OUR BALL INJECTORMEET YOUR PRODUCTION TARGETS WITH GNC

Even though demand continues to climb, oil & gas has reached a challenging crossroads. Those businesses that are able to innovate and pivot to meet evolving environmental regulations and rising costs will thrive. By partnering with GN, you can help ensure you’re among them.