services

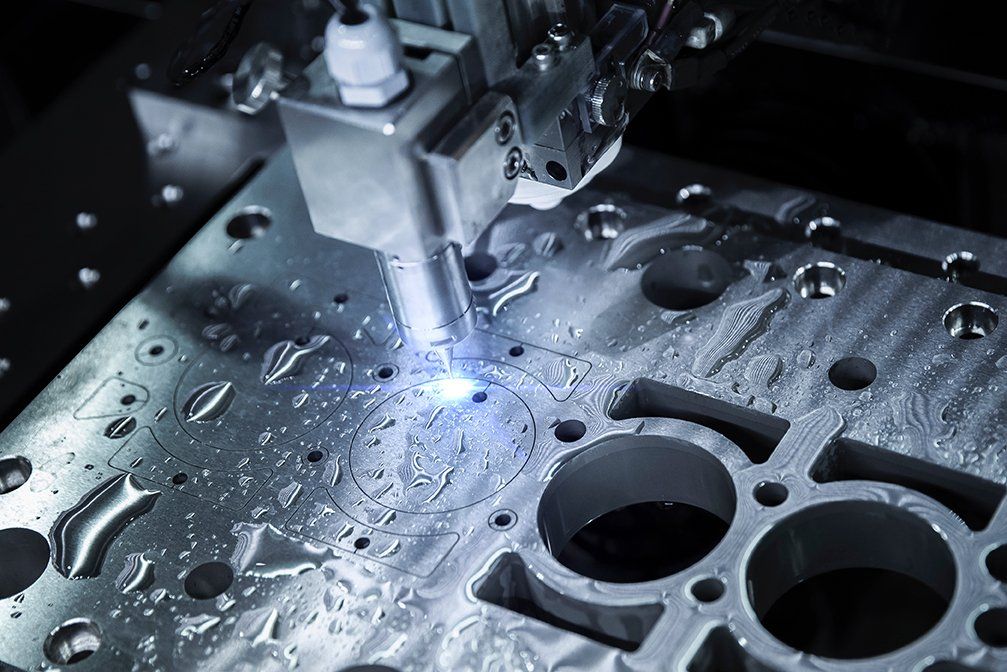

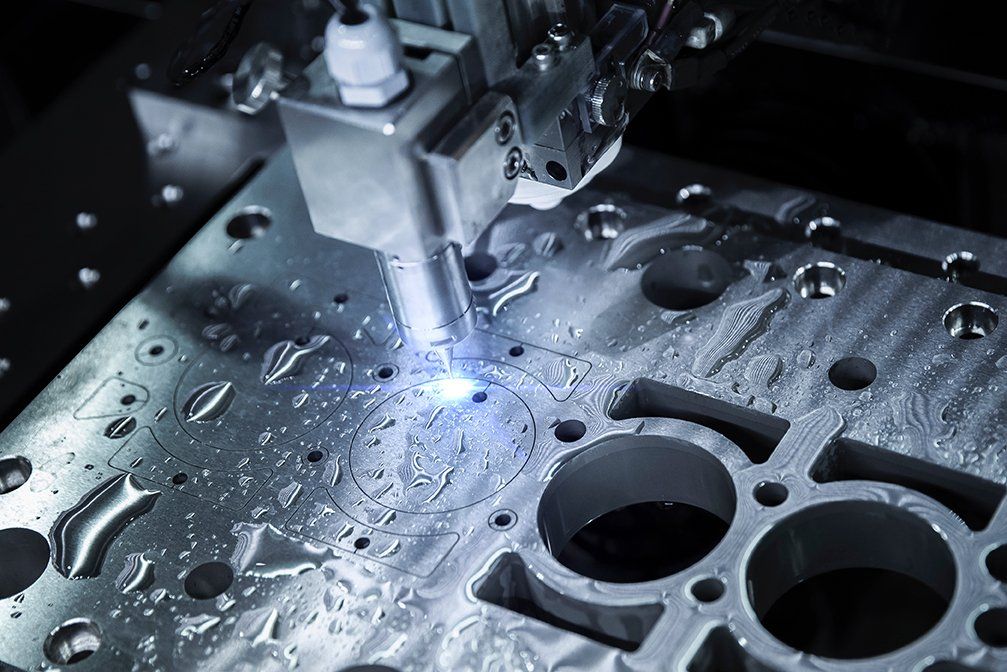

WATERJET CUTTING SERVICES

Precise Fabrication Without Compromising Integrity

Manufacture complex components without jeopardizing their structural integrity with GN Corp’s Tier-1 waterjet cutting services.

Other fabrication methods can risk weakening the material, but a waterjet cutting machine will get the job done with durable final results. Our leading-edge waterjet cutting machines can handle anything from steel to glass.

inquire about waterjet cnc cutting

POWERED BY GN 4.0

TIER-A MANUFACTURING

PRECISE FABRICATION

QUALITY FIRST APPROACH

Industries We Serve

GN Corp has worked with customers in a wide range of industries over our 55+ years in operation. Our customers depend on our precise and optimized waterjet CNC cutting services to fabricate the durable components they require. Our waterjet cutting services have served customers in:

OUR WATERJET CUTTING SERVICES

GN Corporations is always at the forefront of CNC water jet cutting services, adopting the latest machinery and leading-edge software to power our precision-focused services. Partnering with GN Corp allows you to benefit from our latest technology and decades of experience.

Our waterjet cutting services are capable of cutting most materials, including:

- Steel

- Stone

- Glass

- Rubber

- Metals

- Food

- Quartz

- Textiles

WATERJET CUTTING TAILORED TO YOUR NEEDS

We understand that most customers will have unique waterjet cutting requirements. No two jobs are the same, and whether you need waterjet cutting steel or rubber, we’ve got you covered.

Our decades of experience and cutting-edge technology allow us to meet your specific needs. Customization options include:

- Abrasion

- Complex Designs

- Wide Range Of Material Thickness

- Quality Assurance

- Packaging

- Shipping

Our industry-leading waterjet cutting services are designed to meet your exact needs rather than a simple one-size-fits-all approach. Instead, we’ll work with you to learn your unique requirements and tailor our machines and software to meet them.

WATERJET CUTTING POWERED BY GN 4.0

We’re committed to embracing cutting-edge technologies to improve and streamline our services—the result is GN 4.0. Our handcrafted platform leverages the advances of Industry 4.0 and gives you access to the technologies driving the Fourth Industrial Revolution.

Our GN 4.0 platform includes the latest in machine learning, AI, the Industrial Internet of Things, and automation. Our waterjet CNC cutting machine leverages these technologies to optimally complete your order, ensuring that it’s on schedule and on budget.

Our transformative platform is composed of specific valuable solutions, including:

QUALITY 4.0

ANALYTICS 4.0

SUPPLY CHAIN 4.0

ADVANCED MACHINING 4.0

waterjet cutting faq

Have a question? Read our FAQ for more information, or contact us with other inquiries.

How much does waterjet cutting cost?

Every project will have a unique cost, and we’ll give you a quote before we start. Our quotes are primarily based on a few essential factors:

- Material type: What materials will we be cutting? Different materials have varying requirements and influence the total cost. For example, waterjet stone cutting will require higher pressure and abrasive materials, influencing the final cost.

- Material thickness: The thicker the material, the longer the project will take. Cutting a five-inch length in a ½ inch-thick plate of steel will go much quicker than the same length in a 3-inch plate.

- Dimensions of the final product: Your final dimensions tell us how to leverage the above variables to arrive at a quote.

What types of material can waterjet cutting handle?

One of the primary advantages of waterjet cutting is its versatility to work with a wide variety of materials without jeopardizing the structural integrity of the final product. Waterjet cutting glass projects are a prime example of how this technology can handle delicate materials.

For comparison, plasma cutting is an excellent option for some materials, but with others, the high heat it requires can impact the integrity of the end result.

What is the maximum thickness of waterjet cutting?

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.

WHY WORK WITH GN

Your Tier-1 Partner for Accurate Waterjet CNC Cutting Services

Our commitment to quality and predictable costs keeps our customers coming back. Book a consultation today to speak to our fabrication experts to discover how our waterjet cutting services are perfect for your next project.

BOOK A CONSULTATION