services

5 AXIS CNC MACHINING SERVICES

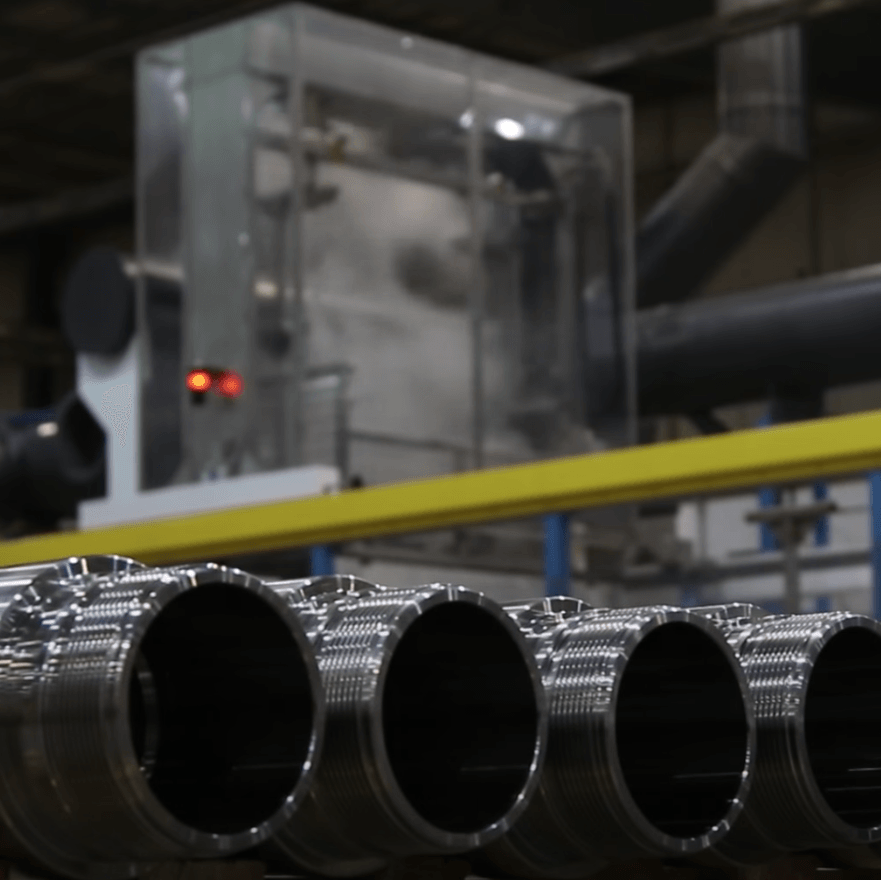

EXPERIENCE PRECISION & EFFICIENCY WITH GN’s 5 AXIS CNC MACHINING SERVICES

Computer Numerical Control (CNC) is a transformative machining process allowing for new levels of precision, tolerance, and durability.

The process allows polyhedron and intricate custom CNC machined parts to undergo rapid prototyping and production without sacrificing accuracy or structure integrity.

GN provides 5 axis CNC machining services that meet and exceed industry standards. Contact us to request a quote for your next project.

get a cnc machining quote

WHAT IS 5-AXIS CNC MACHINING?

A 5 axis CNC service can provide unprecedented levels of accuracy for customized polyhedrons and intricate components compared to conventional methods.

The five axes are the typical X, Y, and Z linear axes plus two rotary axes perpendicular to the other three. The result is a unique ability to process components with complex shapes and require precision.

Maximum Part Size for 5-Axis CNC Machining

5-axis CNC machining has limitations on part size, as the process takes place within self-contained equipment. The maximum workpiece size is:

- Maximum Workpiece Diameter: 33″

- Maximum Workpiece Height: 35″

Components that exceed these sizes may be able to use 9-axis CNC milling, as it has higher maximums.

5 Axis CNC Machining Surface Finishes

One reason CNC machining has become so popular is its capability to work with a wide range of materials. GN’s 5-axis CNC machining can work with the below materials:

- Low Alloy Steels (4140, 4145, 4130, 4330V)

- Chrome (9 CR, 13 CR, 25 CR)

- Corrosion Resistant Alloys (Stainless Steels, Inconel, Incoloy)

- Aluminum

- Titanium

- Copper (BeCu)

- Magnesium

- Composite

5 Axis CNC Machining Surface Finishes

- As Machined

- Fine Machining

- Polishing

- Brushing

- Bead Blasting

GN’s on-machine surface finishes can achieve 4 micro inches, allowing us to provide precision at every process step.

5 Axis CNC Machining Tolerances

Product tolerances are crucial for the types of components manufactured with 5-axis CNC milling. Our CNC services produce tolerances down to ± .0002″ to provide you with the precision necessary for complex components that are integral to the final product or equipment.

GN HAS HIGH STANDARDS FOR 5 AXIS CNC MACHINING SERVICES

High STandards For everything We do

We have high standards for everything we do, including our 5-axis machining. GN maintains full compliance with industry certifications and standards, including AS9100D, Controlled Goods Program, and relevant ISO standards.

INDUSTRY LEADER

GN is also a leader in Industry 4.0 with our GN 4.0 processes that leverage the latest in machine learning, artificial intelligence, and automation to produce the best possible components.

5 Axis CNC Machining FAQs

What is 5-axis CNC machining, and how does it differ from traditional CNC machining?

5-axis CNC machining enables simultaneous movement along five directions, making it perfect for creating complex parts in a single setup. This capability significantly reduces production time and boosts accuracy for intricate components.

What types of industries benefit from 5-axis CNC machining?

Industries like aerospace, automotive, medical, and oil and gas rely on 5-axis CNC for parts that require precision and complex geometries. For example, aerospace components often demand extremely tight tolerances and unique shapes, which are achievable through 5-axis machining.

What materials can be processed with 5-axis CNC machining?

Our machines work with a wide array of materials, including metals like aluminum, titanium, and stainless steel, as well as composites. Each material requires specific tools and settings to maximize precision, which we customize for each project. Explore our material guide for details on selecting the best material for your part requirements.

What are the advantages of using 5-axis CNC machining for complex parts?

5-axis CNC machining offers increased precision, faster production, and reduced handling. These benefits make it cost-effective, especially for parts that need multiple angles or intricate shapes.

What tolerances can GN Corporations achieve with 5-axis CNC machining?

We achieve tolerances as tight as ±0.001 inches, ideal for industries requiring high-precision parts. Precision is crucial for components that must meet stringent quality standards, such as medical devices and aerospace parts.

READY TO GET STARTED?

Our 5 axis machining service strives to produce precise, durable components on time and on budget. Ready to get started? Contact us to get a CNC machining quote today .

get a cnc machining quoteWhy Partner With GN?

INDUSTRY CERTIFICATIONS

AS9100D

ISO 9001:2015

ISO 45001:2018

ISO 14001:2015

Controlled Goods Program

Experience the GN Difference

To learn more about our protective coating services — and what else we can offer — book a consultation now.

GET STARTED