How to Choose the Right Wellhead Isolation Tool for Your Oil & Gas Operation

Precision and safety are vital in the world of oil and gas. Keeping workers safe, preventing unscheduled downtime, and maximizing production throughput depends on using the right equipment.

Wellhead isolation tools are essential for maintaining a safe and efficient operation. Whether you need a fracking wellhead or have a traditional operation, you need to know how to choose the right tool for the job.

Isolation equipment is often used with wireline, coiled tubing, or other intervention methods to control the well and perform necessary tasks, including changing wellhead equipment entirely or conducting downhole inspections.

Additionally, it’s essential to have strict inspection, maintenance, and replacement procedures for oil and gas wellheads to identify and correct any issues before they escalate into major problems. So, let’s dive into how you can navigate the process of selecting the right wellhead isolation tool to meet your specific needs.

What is a Wellhead Isolation Tool?

Wellhead isolation tools come in various designs and configurations, each focusing on specific needs throughout oil and gas or other industries that need precise control over liquids.

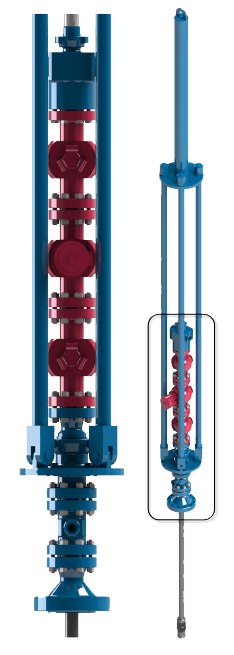

An isolation tool generally consists of valves, seals, and other components that can be remotely operated from the surface. A

wellhead

isolation tool is a specialized piece of equipment used to ensure the safety and integrity of oil wellheads during inspections, maintenance, and repair.

These tools are designed to isolate and seal off the oil wellhead, effectively stopping the flow of fluids from the wellbore to the surface. Being able to stop the flow from the wellbore is necessary for several reasons, such as:

- Safety: Wellhead isolation tools are used to prevent the release of potentially dangerous substances during maintenance or inspection.

- Environmental protection: Making sure that no fluids escape from the wellbore is essential for environmental protection. Oil and gas spills can have severe ecological consequences, so preventing such incidents is a top priority.

- Regulatory compliance: Many regulatory agencies and industry standards require wellhead isolation tools during well inspection and maintenance activities. Having a malfunctioning or ineffective isolation may risk compliance standing.

What to Consider When Choosing an Oil Wellhead Isolation Tool

The specific type of oilfield wellhead isolation tool used can vary depending on the well's characteristics and the industry standards and regulations relevant to your operation.

Several factors should be considered when selecting a wellhead isolation tool to ensure the safety and efficiency of well operations. A few key factors to consider include:

- Compatibility with equipment and operation requirements: Choose a wellhead isolation tool that seamlessly integrates with the existing equipment and meets the well’s specific operational requirements. Starting with compatibility ensures smooth functioning and minimizes the risk of complications in the future.

- Pressure and temperature rating: Assess the tool's pressure and temperature ratings to ensure it can withstand the conditions within the wellbore. Opt for a tool with appropriate ratings that prevents equipment failure and maintains well integrity.

- Material and corrosion resistance: Several possible types of materials are used in wellhead isolation tool manufacturing. Depending on your operation, you’ll need to choose materials that resist corrosion and erosion. Additionally, durable materials extend the tool's lifespan and reduce the need for frequent replacements or maintenance.

- Ease of installation and maintenance: Prioritize tools that are easy to install, operate, and maintain. Simplicity in these aspects saves time and reduces the chances of errors.

- Cost-effectiveness: Evaluate the overall cost of ownership, including initial purchase price, installation, maintenance, and potential downtime. A cost-effective wellhead isolation tool provides a balance between performance and budget constraints while ensuring safety and compliance with industry standards.

Understanding Different Types of Wellhead Isolation Tools

Wellhead isolation tools come in various designs and configurations, but they generally consist of valves, seals, and other components that can be remotely operated from the surface. There is a wide range of types of isolation tools, but for the oil and gas industry, we can focus on the most commonly used tools, which are:

- Single and double block and bleed valves: This type of isolation tool provides a single sealing point, while double block and bleed valves offer two. The result is enhancing safety by reducing the risk of leaks and providing built-in redundancy.

- Dual expanding gate valves: These tools ensure well integrity by using two expanding gates to create a secure and reliable seal and prevent fluid flow. Their robust design makes them well-suited for the harsh conditions of the oil and gas industry.

- Ball valves: By using a spherical disc, ball valve tools can control fluid flow. These types of tools can be quickly opened or closed, providing a tight seal. Ball valves are often used for emergency wellhead isolation.

- Flanged gate valves: It’s common to find flanged gate valves used for wellhead isolation and control. These types of isolation tools employ a gate-like disc to control fluid flow through the wellhead oil and gas. Flanged connections provide a secure and leak-free seal, making them a reliable choice for wellhead applications.

The choice of a particular type depends on factors such as well design, the nature of the operation, and regulatory requirements. Additionally, make sure to choose one of the top wellhead manufacturers to have confidence in your new piece of equipment.

Benefits of Using the Right Wellhead Isolation Tool

Using the correct wellhead isolation tool for your operation offers numerous benefits. Your decision has the potential to create several valuable benefits throughout the operation. Let’s break down a few possible benefits after choosing the correct isolation tool.

Enhanced Safety and Control

Choosing the appropriate wellhead isolation tool is a necessary step in ensuring the safety of oil and gas operations. An isolation tool provides a crucial barrier to prevent uncontrolled fluid releases during well maintenance, which in turn reduces the risk of blowouts and environmental disasters.

Wellhead isolation tools enhance well control by allowing operators to intervene safely, protecting personnel, equipment, and the surrounding environment. However, the correct isolation tool must be used.

Increased Operational Efficiency

Efficiency is key in the oil and gas industry, and wellhead isolation tools are important in the operation. By swiftly and securely sealing off gas wellheads during maintenance or inspections, operations can proceed smoothly and without unnecessary delays. Efficiency translates into reduced operational costs, faster project timelines, and improved productivity.

Cost Savings and Reduced Downtime

A wellhead isolation tool can lead to substantial cost savings over the life of a well by preventing unplanned shutdowns and mitigating the risk of costly incidents. Reduced downtime translates to a more productive operation and fewer disruptions, maximizing the revenue potential of oil and gas assets.

Compliance with Regulatory Requirements

The oil and gas industry is subject to strict regulations to protect both personnel and the environment. Using the correct wellhead isolation tool helps maintain compliance with these regulations. Compliance not only avoids penalties but also promotes sustainable energy practices.

Factors to Consider for Maintenance and Replacement

Oil and gas operators can uphold operational integrity, safety, and efficiency while minimizing risks and downtime by adopting a proactive approach to maintenance and replacement. You’ll need to consider several key factors when evaluating the maintenance and replacement of wellhead isolation tools in oil and gas operations, such as:

- Develop regular inspection and maintenance practices: Implement an inspection and maintenance schedule for the wellhead isolation tool. Regular checks and maintenance practices ensure its continued reliability and performance.

- Know how to spot signs of wear and deterioration: Pay close attention to signs of wear, corrosion, or deterioration on the wellhead isolation tool. Wear may include visible damage, loss of sealing effectiveness, or changes in performance. Schedule repair or replacement once identified to prevent potential failures.

- Understand when to replace a wellhead isolation tool: Determine the criteria for replacing it while it still performs as intended. Factors to consider may include:

- Age

- The extent of wear or damage

- Changes in regulatory requirements

- Advancements in technology that offer improved safety and performance

While you can handle inspection and replacement in-house, some organizations offer isolation equipment services to keep your equipment operating as expected or replaced before it malfunctions.

What’s the Right Isolation Tool for You? Final Considerations

Choosing the correct wellhead isolation tool for your specific operation is of the utmost importance. Your choice directly impacts safety, efficiency, and regulatory compliance. The right wellhead isolation tool has the potential to meet precise operational requirements and well conditions and allows operators to have the well control they need.

Remember to consider compatibility, pressure and temperature ratings, material durability, ease of use, cost-effectiveness, and emergency response capabilities.

You’ll also need to create diligent maintenance and inspection practices to stay on top of signs of wear and tear. Don’t skip this step; it’s crucial to prolong the tool's lifespan and prevent unexpected failures.

Ultimately, selecting the right wellhead isolation tool is vital to the overall success and management of oil and gas wells.

GN Corp is a leading provider of customized wellhead isolation tools. We can work with your precise needs to develop a tool with the right connection, configuration, and requirements for your operation while keeping you in full compliance with any regulations.

Do you need a replacement or upgrade isolation tool?

Contact us today to learn more about how we can help.