Precision CNC Machining 101: Key Principles, Processes, and Best Practices

Defining Precision CNC Machining

- Basic Terminology: CNC (Computer Numerical Control), axis definitions, subtractive manufacturing.

- Historical Perspective: Short overview of how CNC evolved from manual machining.

- Relevance Today: Industries that rely heavily on precision (aerospace, oil & gas, automotive).

Core Components of a CNC System

- Hardware Elements: Machine tool, spindle, axes, control panel.

- Software & Programming: CAD/CAM software, G-code, M-code basics.

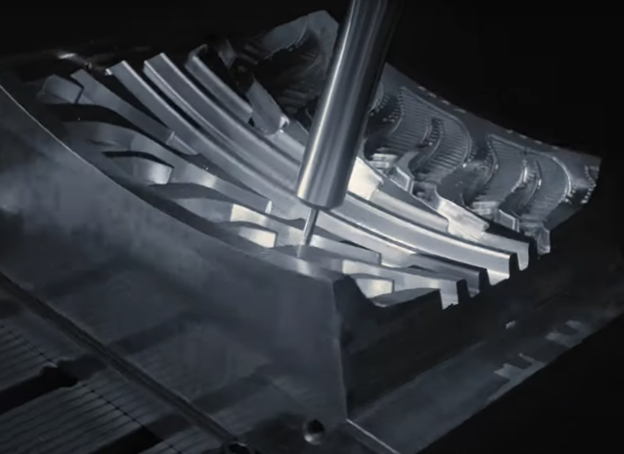

- Tools & Toolholders: Types of cutters (end mills, drills, lathes) and their impact on precision.

CNC Machining Processes

- Milling: Common operations (face milling, peripheral milling) and when to use them.

- Turning: Key concepts like threading, grooving, and contour turning.

- Drilling & Boring: How precision drilling compares to other machining operations.

- Additional Processes: EDM, grinding, and how they fit into a CNC shop.

Key Benefits of Precision CNC

- Accuracy & Consistency: Achieving tight tolerances across multiple runs.

- Efficiency & Scalability: How CNC reduces production time and handles mass production.

- Versatility: Materials (metals, plastics, composites) that can be machined.

- Reduced Human Error: Importance of proper programming and minimal manual intervention.

Challenges & Limitations

- Initial Investment: Machines, software, and skilled operator costs.

- Complexity: Need for specialized CAD/CAM training.

- Maintenance Requirements: Machine calibration, tool wear, and regular upkeep..

Future Trends in Precision CNC

- Digital Integration: IoT sensors, real-time monitoring, predictive maintenance.

- AI and Machine Learning: Potential for adaptive machining processes.

- Sustainability and New Materials: Focus on energy-efficient machining and biodegradable materials.